Medical Equipment Tracking

For over 20 years we've helped hospitals lower costs by tracking the movement and utilization of medical equipment, instruments, supplies, personnel and patients.

The ABGI AllTraq system is the only commercially available system to utilize FDA approved ultra wideband technology.

Biomedical Fact from Himss.org

40%

32,000 hours

32,000 hours

Biomedical Engineers spend up to 40% of their time searching for equipment.

32,000 hours

32,000 hours

32,000 hours

Nurses spend around 32,000 hours a year searching for equipment.

Find Equipment Instantly

The ABGI AllTraq system allows you to track the location and utilization of any piece of equipment in the hospital. In addition, you can track equipment usage to the patient level helping you improve care and meet regulatory requirements.

With AllTraq you can:

- Quickly find any piece of medical equipment

- Track equipment use to the patient level

- Detect usage trends to improve future care

- Reduce costs from lost, damaged or stolen inventory

- Assure full utilization and reduce unnecessary rentals

- Automate the charging or cost accounting process

- Automate manual recording tasks

- Manage instrument acquisition and maintenance

- Manage inventory of sets, packs or trays

- Automate the documentation of instrument sterilization

- Automate the documentation of sterilizer utilization

- Create productivity tracking records for each employee

- Monitor temperature on refrigeration units

- Track equipment use in home health care

How It Works

View location data overlaid on your existing floor plans

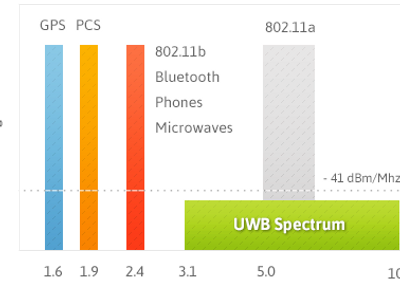

The AllTraq system uses a unique combination of radio frequency identification tags (RFID), ultra wideband frequency (UWB) and easy to use software. The system gives you GPS-style tracking in and out of the building. It is low cost, low power, non-interfering and jam resistant.

Tags and/or barcodes are placed on items to be tracked and sensors are placed strategically at the hospital's discretion. The current location of any asset can be viewed on a computer or handheld device. You can view location data overlaid on your existing floor plans making it easy to locate any asset.

The software also provides completely automated and customizable reports for regulatory compliance, including TJC, employee productivity indicators and cost reduction.

Ultra Wideband RFID Tags

Our system has greater accuracy, less interference and lower cost than any other system on the marke

ABGI's AllTraq system is the only UWB system capable of transmitting data over the distance necessary with the accuracy and density capability needed in the healthcare industry. For healthcare, UWB is superior for encryption and meets HIPAA standards for privacy.

The FDA has approved UWB for use in the operating room and has recognized that UWB technology satisfies operating room requirements for medical-grade wireless video systems. UWB's lower RF output power allows same channel reuse in adjacent rooms and results in low interference with other signals.

Data Matrix Barcodes

A Medidot ® Data Matrix barcode encodes as much data as a traditional barcode in one-tenth the space and can be adhered to or laser etched into the instrument.

Redundancy within the symbology makes the barcode readable even if 60% of the image is damaged. The instrument can then be scanned with a handheld device.

- Harvester Sanitation

- Sterilizable Tags

- Safety Badges

- Medical Equipment Traq

- Temperature Traq

- Weapons Tracking

- Firearm Safety

- Infant Elopement

- Livestock Tracking

- Equipment Tracking

- AllTraq Pet Carrier

- Railroad Tracking

- Tactical Helicopter

- Unmanned Ground Vehicle

- Files & Video

- About

- Client Sign In (CAP)

- Client Sign In (AllTraq)

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.